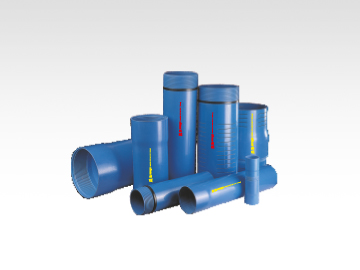

Application

- Corrosion resistant uPVC Casing Pipes for bore-well & tube-well.

- BSP Series sizes 1-1/2" to 10".

- Best suitable for shallow and medium bore.

- Generally resistant to most acids, bases, salts, aliphatic solutions, oxidants, and halogens

Scope

Outlined specification IS, DIN. This pipe is intended for use in applications where the fluid conveyed does not exceed 60oC.

PVC Materials

The material used in the manufacture of the pipe shall be domestically or imported from reputed manufacturer produced rigid polyvinyl chloride (PVC) compound, PVC Resin grade K-6701.

Dimensions

UPVC Casing Pipes shall be manufactured in strict accordance to the requirements of IS: 12818-1992 or as per International standard for physical dimensions and tolerances. Each production run of pipe manufactured in compliance to this standard, shall also meet or exceed the test requirements for materials, workmanship, impact strength, specific gravity, tensile strength, vicat softening temperature test content as defined in IS: 12818-1992. Pipes thread and slot sizes which meet the dimensional requirements as defined in IS: 12818-1992 or as per international standard.

Dimensions of uPVC Casing Pipe – CS as per IS: 12818 – 2010 (Suitable for wells depth up to 80 meters)

Size in

Inch | Nominal diameter

(DN) | Outer diameter of Pipe

(mm) | Thickness of Pipe

(mm) | Outer dia over

connection | Segmental Length

(mm) | Pipe length with socket

(mm) |

| 4"* |

100 |

113.0-113.2 |

4.0-4.4 |

117 |

45 |

3.06 |

| 4.5"* |

115 |

125.0-125.4 |

- |

- |

- |

3.07 |

| 5"* |

125 |

140.0-140.4 |

4.9-5.4 |

148 |

60 |

3.08 |

| 6"* |

150 |

160.0-165.4 |

5.7-6.5 |

173 |

60 |

3.08 |

| 6.5"* |

165 |

180.0-180.5 |

5.7-6.5 |

189 |

60 |

3.08 |

| 7"* |

175 |

200.0-200.5 |

7.0-7.8 |

212 |

60 |

3.09 |

| 8"* |

200 |

225.0-225.5 |

7.6-8.8 |

238 |

70 |

3.1 |

| 9"* |

225 |

250.0-250.5 |

8.6-9.8 |

- |

- |

3.11 |

| 10"* |

250 |

280.0-280.5 |

9.6-11.0 |

292 |

85 |

3.11 |

Dimensions of uPVC Casing Pipe – CM as per IS: 12818 – 2010 (Suitable for wells depth up to 250 meters)

Size in

Inch | Nominal diameter

(DN) | Outer diameter of Pipe

(mm) | Thickness of Pipe

(mm) | Outer dia over

connection | Segmental Length

(mm) | Pipe length with socket

(mm) |

| 1" |

35 |

42.0-42.2 |

3.5-4.0 |

46 |

25 |

3.04 |

| 1.5" |

40 |

48.0-48.2 |

3.5-4.0 |

52 |

25 |

3.04 |

| 2" |

50 |

60.0-60.2 |

4.0-4.6 |

64 |

30 |

3.05 |

| 3" |

80 |

88.0-88.2 |

4.0-4.6 |

94 |

40 |

3.06 |

| 4." |

100 |

113.0-113.2 |

5.0-5.7 |

120 |

45 |

3.06 |

| 4.5"* |

115 |

125.0-125.4 |

5.0-5.7 |

132 |

50 |

3.07 |

| 5" |

125 |

140.0-140.4 |

6.5-7.3 |

150 |

60 |

3.08 |

| 6" |

150 |

165.0-165.4 |

7.5-8.5 |

177 |

60 |

3.08 |

| 6.5"* |

165 |

180.0-180.5 |

7.5-8.5 |

193 |

60 |

3.08 |

| 7" |

175 |

200.0-200.5 |

8.8-9.8 |

215 |

60 |

3.09 |

| 8" |

200 |

225.0-225.5 |

10.0-11.2 |

243 |

70 |

3.1 |

| 9"* |

225 |

250.0-250.5 |

11.8-12.9 |

- |

- |

3.11 |

| 10" |

250 |

280.0-280.5 |

12.5-14.0 |

298 |

85 |

3.11 |

Specification for Deep Well Plain Casing Pipe Conforming as per DIN 4925

Nominal Dia.

Inch mm |

Outside Dia.

Min. Max. |

Nominal Dia.

Min. Max. |

Max. Outside Dia. Over Socket mm

Collapse Resistance kg/cm² |

| 4" 100 |

113.0 113.3 |

7.0 7.9 |

125 15.5 |

| 4.5" 115 |

125.0 125.3 |

7.5 8.5 |

137 15.5 |

| 5" 125 |

140.0 140.4 |

8.0 9.0 |

152 15.5 |

| 6" 150 |

165.0 165.5 |

9.5 10.7 |

180 15.5 |

| 7" 175 |

200.0 200.5 |

11.5 13.3 |

215 7.5 |

| 8" 200 |

225.0 225.5 |

13.0 14.8 |

247 15.5 |

| 10" 250 |

280.0 280.5 |

16.0 17.6 |

304 15.5 |

Specification for Medium Well Plain Casing Pipe Conforming as per DIN 4925

Nominal Dia.

Inch mm |

Outside Dia.

Min. Max. |

mm Wall Thickness mm

Min. Max. |

Max. Outside Dia. Over Socket mm

Collapse Resistance kg/cm² |

| 1.5" 40 |

48.0 48.2 |

3.5 4.1 |

53 32.0 |

| 2" 50 |

60.0 60.2 |

4.0 4.6 |

66 24.0 |

| 3" 80 |

88.0 88.3 |

4.0 4.6 |

94 7.5 |

| 4" 100 |

113.0 60.2 |

5.0 5.7 |

121 7.5 |

| 4.5" 115 |

125.0 125.3 |

5.0 5.7 |

132 7.5 |

| 5" 125 |

140.0 140.4 |

6.5 7.4 |

149 7.5 |

| 6" 150 |

165.0 165.4 |

7.5 8.5 |

176 7.5 |

| 7" 175 |

200.0 200.5 |

8.8 9.8 |

215 7.5 |

| 8" 200 |

225.0 225.5 |

10.0 11.2 |

241 7.0 |

| 10" 250 |

280.0 280.5 |

12.5 14.0 |

297 7.0 |

Details

| Slot Width |

min. mm |

0.2 |

0.3 |

0.5 |

0.75 |

1.0 |

1.5 |

2.0 |

3.0 |

| Tolerance |

|

+.06 |

+.08 |

+0.1 |

+0.2 |

+0.2 |

+0.2 |

+0.2 |

+0.3 |

| Slot Width |

*inch no. |

8 |

12 |

20 |

30 |

40 |

60 |

80 |

120 |

* Slot numbers designate width of openings in thousand part of an inch. no. 40 is an opening of 40/100".

Note : Tolerance for 0.3 mm slot is +0.06 mm conforming to IS:12818. Other values are same.